Moulding & Insert Moulding

We are experts in different types of moulding including plastic injection moulding and insert moulding. We are also specialists in low pressure moulding.

Injection moulding

Our injection moulding plant comprises of Arburg and Engel horizontal machines from 15 – 220 tonnes with 2 shot, vertical and rotary table machines up to 100 tonnes for insert moulding. Within the group we have machines up to 1100 tonnes.

Using robot load and unload systems combined with part-specific jigs and fixtures we can manufacture high-volume moulded components in the most cost-effective manner.

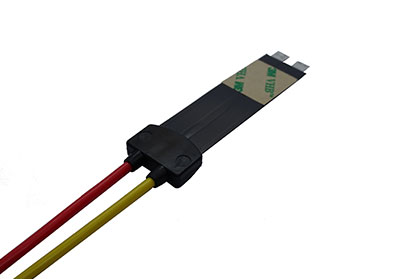

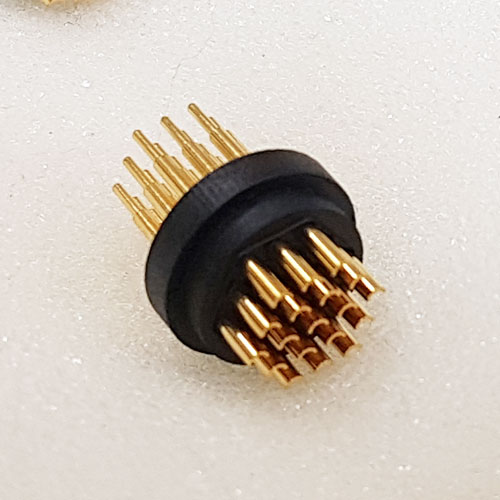

Low pressure moulding

This is a process that uses thermoplastic polyamides injected at low temperature and low pressure. This process is used to encapsulate and environmentally protect electronic components and connectors, it is also used for sealing connectors and to create strain relief on cables and wires.

We process many engineering polymers, including:

Nylon (PA6, PA66)

Acetal (POM)

Polyphenylene sulphide (PPS)

Polycarbonate (PC)

Elastomers (TPE, TPV, TPU)

Liquid-crystal polymer (LCP)

Our experienced team of engineers work with our customers from initial product concept through material selection, moldflow software, mould tool design & manufacture, product & process implementation and into full production.

By working with Labone you will get the benefits of the full range of our capabilities and knowledge to help make your components the best they can be.

To find out more about our moulding and insert moulding solutions call us on +44 (0)115 944 8800 or